Spencer Courtyard, Finchley, London

IKO Armourplan PVC

Project: Spencer Courtyard, Finchley, London

Architect: kennedytwaddle

Developers: Monbally

Main Contractor: Lyons & Sons

Roofing Contractor: AJ Lucas Roofing Ltd

Waterproofing membrane: IKO Armourplan PSG PVC single ply membraneIntroduction

Sustainability and creating a lush, haven of greenery were key considerations for award-winning architects and designers kennedytwaddle when turning a derelict eyesore into a scheme of contemporary homes in Finchley London.

About the project

Spencer Courtyard is a development of three new build single storey houses, each with their own private courtyard, and a partial rebuild of an existing two storey-block to create another two apartments.

Tucked behind terraces which front Regents Park Road, the small, brownfield site was originally a timber yard which is closely overlooked by the neighbouring properties. Due to its location, the architects knew that engaging with the local community was of paramount importance and involved them throughout the design process.

Gaining planning permission required careful consideration and kennedytwaddle adopted a sympathetic approach to the design of the properties. This included orientating the houses to offer the most privacy to the homeowners and surrounding houses. Daniel Bosworth, technical manager at SIG Design & Technology worked with the architects to develop the roofing specification to support the process.

Choice of materials was very important in this context and the architects opted for natural, tactile materials, such as brick and timber and large windows to ensure the interiors get plenty of natural light. Wanting to promote biodiversity within its urban setting and provide an aesthetically pleasing view […]

Imperial Court

IKO Armourplan PVC, IKO PermaTEC Hotmelt, Liquid Waterproofing

Project: Imperial Court

Developer: Featherstone Homes

Roofing contractors: AJ Lucas Ltd

Roof membrane systems:

IKO Armourplan PSG PVC single ply

IKO Permatec Hot Melt

Hydrostop AH+ liquid waterproofingSituated on the trendy Streatham high street and only 17 minutes from Central London, Imperial Court has been designed to meet the growing need for well designed but affordable developments in the competitive London market.

Previously a collection of single-storey light industrial buildings, the area was most recently used as an MOT and repair centre specialising in the repair and servicing of coaches, buses and cars. Featherstone Homes’ flagship scheme, the site has been redeveloped into a gated development of 1, 2 and 3-bedroom apartments with undercroft parking and commercial units.

Three waterproofing solutions

Decisions regarding roofing specification should always be made on a project-by-project basis and one membrane will not necessarily meet the demands for the entire build. With a terraced area providing amenity space, balconies to each apartment and a flat roof area supporting solar panels, Imperial Court presented three distinct waterproofing areas. Each area necessitated a different solution.

Having worked with them on a previous project, Featherstone Homes had no hesitation in asking AJ Lucas Roofing Ltd to provide the solution and meet the high expectations for this project.

Antony Lucas Managing Director at AJ Lucas agrees “The fewer problems housing developers have on site the better. They want to work with companies who they can trust to supply and install the correct solution. It means they have one less thing to consider.”

AJ Lucas is […]

NHS Isolation Wards Norfolk and Norwich University Hospitals

IKO Armourplan PVC

Project: NHS Isolation Units

Client: Norfolk and Norwich University Hospitals NHS Foundation Trust

Main contractors: ModuleCo

Roofing contractors: Harold Jones Roofing and Roofworx

Waterproofing membrane: IKO Armourplan P single ply membraneIntroduction

When COVID-19 first hit the UK, NHS Trusts were faced with the demands of increasing specialized intensive care and isolation ward capacity to deal with very sick and highly infectious patients. With the rate of infection escalating the biggest challenge was to create this extra capacity quickly.

Modular construction techniques are ideal for these situations and Norfolk and Norwich University Hospitals NHS Foundation Trust approached ModuleCo to provide a 10 bed High Consequential Infectious Diseases (HCID) Isolation Ward. With the rate of infections escalating rapidly the challenge was to design, construct and commission a fully working ward in only eight weeks setting a new benchmark in off-site construction timescales for these M&E complex facilities.

Modular Units

ModuleCo’s units are assembled almost entirely from pre-engineered components in a controlled factory environment. Each part of the modules such as roof, walls etc. are constructed on rigs in the factory. When each element is ready the module is then put together like a large jigsaw puzzle. This makes constructing units a safer and quicker process than traditional construction methods and it is possible to complete two modular roofs in a single day.

Having worked alongside NHS Trusts for over 20 years, delivering over 135 individual projects across the UK ModuleCo used their extensive experience to design, manufacture and deliver an isolation ward for the hospital […]

Evocative Zinc Roofing and Shingle Cladding at Lady Bee Enterprise Centre

IKO Armourplan PVC, Zinc & Copper

Project: Lady Bee Enterprise Centre, Shoreham Port

Client: Shoreham Port Authority

Architect: ECE Architecture

Main Contractor: Pillbeam Construction

Specialist Roofing and Cladding Contractor: Kingsley Specialist Roofing

Material: elZinc Slate Advance standing seam roofing, elZinc Crystal Shingles and Armourplan membrane gutters

Intro

A rather unusual group of light industrial units have appeared on the dockside at Shoreham Port, one of the largest cargo handling Trust ports on the south coast, located just four miles west of Brighton. We spoke to project architect Martin Gray, client Tim Hague and installer Arron Moore about the project.

About the project

The Lady Bee Enterprise Centre is one of three projects ECE Architecture are working on with Shoreham Port Authority, and it is the least conventional. Though a Design & Build project, it doesn’t look like the conventional set of light industrial units.

Brighton & Hove are known as a ‘digital cluster’ – a focal point of the tech industry, attracting investment and talent to the region. Both Brighton and Hove’s digital and travel economies are worth more than £1billion per annum, and the region needs to nurture small businesses in the area.

Client Tim Hague of Shoreham Port explains the main drivers for the project:

“Shoreham Port is a trust port, meaning we have a duty to boost the local economy and create jobs. We can do this by developing appropriate areas of our estate with commercial units for local businesses. Commercial space in the greater Brighton and Hove area is scarce. Shoreham Port is also an EcoPort and has recently achieved carbon neutral […]

Baxter Green

IKO Armourplan PVC

Project: Baxter Green, Bramcote

Client: Willmark Homes

Architect: Leonard Design

Contractor: William May Developments

Roofing Contractor: K&S Services Nottingham Ltd

Waterproofing membrane: IKO Armourplan PSG PVC single ply membraneIntroduction

IKO Armourplan PSG single ply membrane has been specified for a re-development by Willmark Homes on the former site of St John’s College in Bramcote village, Nottingham. When completed Baxter Green will feature 40 residential properties varying in sizes from apartments to five-bedroom houses.

About the Project

Architects Leonard Design were appointed to create this residential development set in the former gardens of the Grade II listed college. The picturesque scheme has been sympathetically designed to complement the existing buildings and create an exclusive development of luxury homes with a strong connection to the outdoors.

Phase 1 has seen the development of the four and five-bedroom houses which boast a striking three-storey design. The front elevation presents a house of two halves, flat roof areas support a large terrace to one side and a pitched roof on the opposite. The roof provides a distinctive element and appears to wrap around the house flowing from the apex down to ground level. Due to the degree of visibility accorded by the steepness of the slope the concept demanded a roof covering which could meet the high expectations with regard to visual appearance.

Product Choice

The developers had originally wanted to specify a zinc material for the roof areas, however after exploring the options it was deemed to be out of reach in terms of […]

Honiton Community College

IKO Armourplan PVC

Project: Honiton Community College

Main contractors: Mercury Construction

Roofing contractors: RC Roofing

Waterproofing membrane: IKO Armourplan PSGWhile much of the UK’s stock of school and academy buildings is ageing, fortunately, some well-informed educational establishments are now able to deal with the problems caused by leaking roofing systems.

To address building dilapidation issues, academies and sixth form colleges can apply to the government’s Condition Improvement Fund, (CIF). The objective of CIF is to address significant condition need, keeping buildings safe and in good working order. Priority is usually given to projects such as roof, window and central heating replacements.

The CIF process follows an annual bidding round whereby academies apply for extra capital funding. It’s a resource you can turn to when your school roof has reached the end of its useful life. But resources are tight as an increasing amount of schools enter the bidding process.

One clear example of roof disrepair was at Honiton Community College in Devon which also offers sixth form facilities. It converted to academy status in 2011 and was successful in securing £1m of CIF Funding from the DFE for a major refurbishment of the science block.

Approved works comprised a new roof, windows, internal and external doors, new flooring, and decoration throughout. Installation of new mechanical services and new laboratory fixtures and fittings completed the project.

Refurbishments to the college were undertaken by award-winning main contractor, Mercury Construction of Plymouth. Work started […]

The Tree House Clowance Estate and County Club

IKO Armourplan PVC

Project: The Tree House, Clowance Estate

Main contractors: Blue Forest

Roofing contractors: Marnick Roofing

Waterproofing membrane: IKO Armourplan PHome to an aristocratic Cornish family for five centuries, the Clowance Estate and Country Club, Cornwall is one of a kind. The Clowance Estate is set in 97 acres of magnificent landscaped parkland and beautiful woodland setting, some 20 minutes from both north and south Cornish coasts. It provides luxury holiday accommodation all year round.

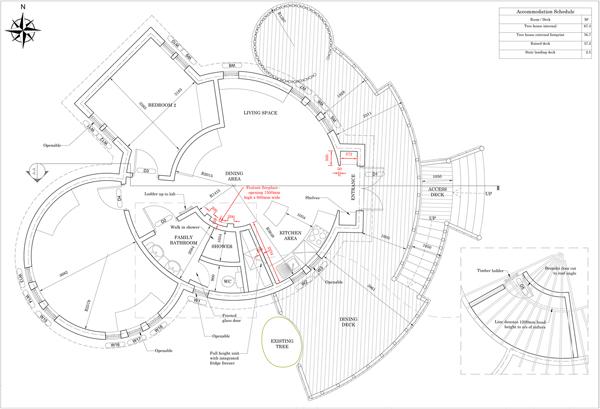

Blue Forest has established a reputation as the world’s leading treehouse consultancy and are renowned for designing buildings that reflect the environment in which they are built. At Clowance, the team at Blue Forest were tasked with creating a two-bedroomed forest retreat consisting of approximately 70 m2 of raised self-contained accommodation plus external balcony and dining deck. The final design for the living area incorporated two main intersecting circular elements (one radius 2600mm and the other 3700mm) and one rectangular zone.

The Tree House is a new build holiday let set in the midst of a forest location and is adjacent to a lake. Its design juxtaposes modern materials and a bold sharp angular concept with the canopy and foliage of an established woodland.

This striking concept demanded a roof covering not only meeting the high expectation regarding visual appearance (due to the degree of visibility accorded by the steepness of the slope) but also capable of seamlessly and robustly dealing with the various conical-to-conical and conical-to-dual pitch valley interfaces and curved fascia detail.

Traditionally, cedar shingles would have been specified. However, in […]

Complete roofing and zinc solution from SIG D&T at Jersey Premier Inn

FDT Rhepanol PIB, Green Roofing, IKO Armourplan PVC, Zinc & Copper

Project: Premier Inn, Jersey

Roof membrane systems:

IKO Armourplan PSG PVC single ply 800m2

Hydrostop AH+ liquid waterproofing detailing

Sedum green roof

FDT Rhenofol CGv PVC single ply 80m2

Installer: KA BaileyZinc cladding:

elZinc Rainbow Brown 1600m2

Installer: Boss MetalsChartered building company: Camerons of Jersey

Travellers have another choice of modern, smart accommodation when they visit Jersey’s capital, with the opening of the island’s first Premier Inn in St Helier earlier this year. The four storey 91 room hotel, situated at the busy Charing Cross interchange near the town centre, features some distinctive external cladding in addition to a well-thought-out roof design.

SIG Design & Technology worked closely with Camerons, a 61-year-old Jersey-based chartered building company in the development of the new-build hotel’s roofing and cladding specification. SIG Design & Technology (SIG D&T) followed their eight-step design and build process, #perfectroof, from product selection and roof design expertise through to complete guarantees and planned maintenance.

Once the client brief was established, SIG D&T’s Specification Manager Christa Coe and Technical Support Manager Paul Jacobs worked together to develop the roofing specification.

Four roofing and cladding systems were selected. IKO’s Armourplan PSG system was chosen to waterproof 800 m2 of the main roof area. Armourplan PSG is a glass tissue reinforced polyester fleece backed PVC membrane suitable for use in a wide range of single ply roofing applications on both flat and sloping roofs. Armourplan PSG offers enhanced mechanical properties over standard PVC membranes and is completely UV stable […]

Church of St Andrew – hat-trick for heritage church refurbishment

IKO Armourplan PVC, Zinc & Copper

Project: Church of St Andrew, Avonmouth

Architect: Innes Wilkin Architect

Roofing contractor: Urban Roof

Waterproofing membrane: IKO Armourplan PVC single ply

Zinc: elZinc SlateFirst built in 1893, extended with a new nave building and tower in 1935, then bombed and burned out during World War Two. Finally, re-built in 1957. The church of St Andrew’s, at Avonmouth, near Bristol, has had a colourful history. The red stone building featured pitched roofing mostly in green-finished patina copper, dating back to 1957, but it had fallen into disrepair.

A key priority was refurbishing the roof of this prominent local landmark building.

Ian Hayward, SIG Design & Technology’s Specification Manager for South West England and South Wales, said: “SIG Design & Technology was chosen for this project because we can offer multiple product expertise including for flat roofs and metals with just one phone call, as well as our depth of knowledge of roofing design.

“We used an eight step process which we call #perfect roof which follows the process from product selection and roof design expertise through to full guarantees and planned maintenance.

“With the help of our roofing contractor, we were able to move quickly on this conservation project and the client was very pleased with the results.”

Three-part roofing challenge

Exterior building works started in October 2017, replacing the church roofs and adding a new entrance foyer, as well as drains and toilets.

Architects Innes Wilkin needed a single point of expert contact […]

The General – Iconic Bristol landmark takes shape, with help from Armourplan PSG

IKO Armourplan PVC

Project: Bristol General Hospital

Architect: City & Country

Main contactor: City & Country

Roofing contractor: Roofworx

Waterproofing membrane: IKO Armourplan PVCStanding in a prominent position overlooking the city’s Harbourside, the former Bristol General Hospital is an iconic and long-admired building.

The Grade II listed site in Lower Guinea Street is now being redeveloped as 205 luxury apartments and houses with between one and four bedrooms, giving the former hospital – which first opened in 1832 – a new purpose.

City & Country, which specialises in the redevelopment of heritage properties, was granted planning permission for their residential scheme on the condition that they could recreate a key feature of the Bristol General which was once highly visible from miles around.

The distinctive Ogee Dome which once capped the unique 25 metre octagonal tower in the south west corner of the building was destroyed during World War Two bombing, in which other parts of the hospital were also heavily damaged. The challenge for the contractors was to painstakingly recreate the dome, with the replica forming part of plans to return the building to its original exterior design of 1853.

Modern materials were employed in the quest to recreate part of Bristol’s heritage. SIG Design & Technology supplied IKO’s Armourplan PSG membrane because it fitted the bill perfectly as the roof covering was ideal for replicating the original seamed lead roof.

Recreating the dome required the employment of skilled carpenters to build a structure 10 metres wide by nine metres high and weighing over 16 tonnes once completed.

The challenge facing […]