Lucent W1: How the complex roof was built

Behind the iconic Lights of London’s Piccadilly Circus has emerged a new mixed use destination development which features one of the most complex roofs ever to be built in the capital. The roofscape of Lucent W1 is built in slate, zinc and hot melt, and its execution was only made possible through a partnership with a multi-product designer and supplier and an experienced multi-disciplinary roofing contractor. Here is the story of how that was achieved.

What is Lucent W1?

Since 1908, Piccadilly Circus has been home to illuminated advertising known as The Lights. London’s most famous billboard first became digitised in 1998 when the longest running advert for Coca Cola was switched from neon to digital projection, and in 2017 Fletcher Priest Architects coordinated the building of a standalone steel structure to support the largest single digital screen in Europe.

The spaces behind The Lights had been empty since the 1950s, but the 13 different buildings in an almost complete city block have now been unified by the same architects into a single development that retains and celebrates the identities of each building and provides visitors to Piccadilly Circus with a new complex of over 13,000m2 of retail, restaurant, offices and luxury apartments.

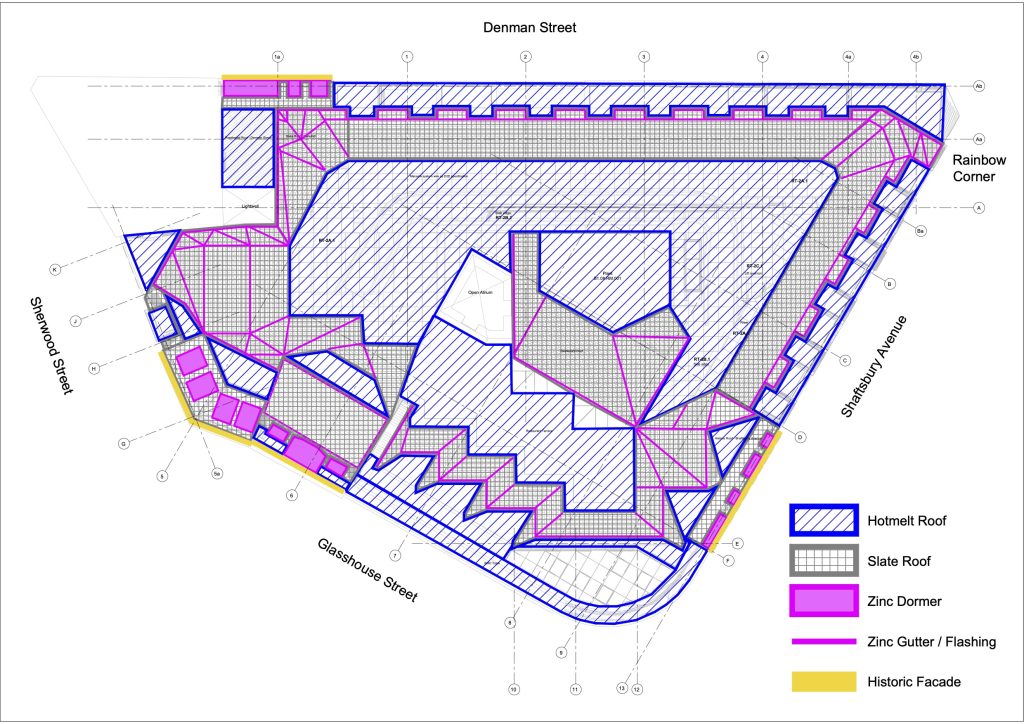

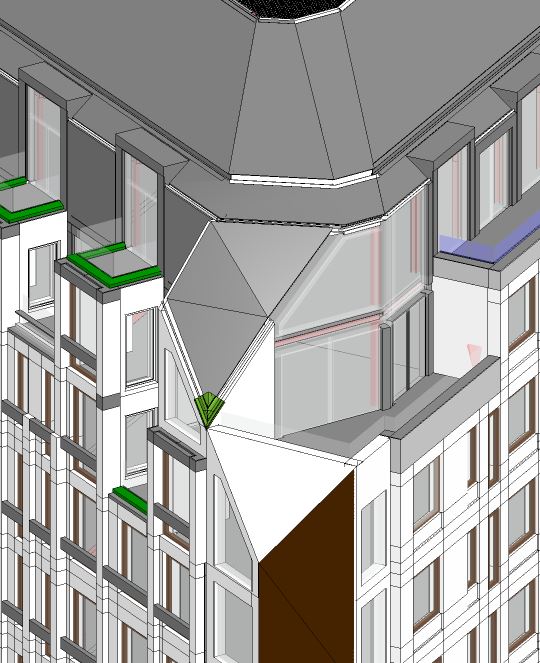

The element which ties all the individual facades and elements together is a complex folding roofscape of slate, zinc and hot melt, incorporating 22 terraces and a rooftop restaurant, knitting into the facades with cascading planes of slate, cladding and dormer windows.

This roof was designed by SIG Design and Technology, working in partnership with their DATAC accredited roofing contractor E J Roberts and main contractor Wates Group to produce one of the most interesting and complex roofs we have ever worked on, and one we can rightly be proud of.

A 360 flyover of the completed roofscape at Lucent W1. Video: Wates Group

The Brief

The architects’ original design intent for the project, set out in the first planning approval of 2016, was for the roof to be a “ceramic lattice mantle of complex folds” that would unify the various facades into a seamless whole and articulate the entrance on Sherwood Street and other significant points in the building, such as Rainbow Corner, the iconic night club at the corner of Denman Street and Shaftesbury Avenue, which was home to US servicemen in the 1940s.

However, as the design developed it became clear that the “ceramic mantle” approach would not meet the cost requirements for the project. The decision was made to execute the main areas of roof covering in folded planes of natural slate.

In addition, the project was to target both BREEAM Outstanding and the Gold WELL Building Standard and was also required to meet stringent fire safety requirements. These constraints restricted most hot works and prevented the use of lead, the traditional method of executing interfaces and rainwater details in slate.

Flashings, cladding and rainwater goods conventionally executed in lead would therefore be carried out in fully supported zinc, together with the dormer window surrounds and sections of the roof that would need to interface with the three historic façades.

Areas of the roofscape at near zero pitch would require the specification of a hot melt waterproofing solution, and some of the slate planes would need to meet falls below those conventionally carried out in slate.

Working In Partnership

To effectively construct a roof that incorporated three high quality roof finishes, the contractors at Wates Group needed to rely on a specialist roofing contractor working alongside a design team and distributor who could design and supply all three, so that all the interfaces would be covered by a single team.

Wates were able to confidently select SIG Design and Technology for the design and supply, and E J Roberts Limited, one of our DATAC contractors, as their specialist contractor, knowing that they would be able to meet all the requirements of such a complex project and had experience working together on multi-material roofs.

E J Roberts is a London based multi-disciplinary roofing contractor with over sixty years’ experience including in hot melt, felt, slate, tiling, hard metals, lead and heritage projects. Their slaters alone who worked on the project have over 100 years’ joint experience in slating.

SIG Design and Technology is part of SIG Plc, one of Europe’s leading suppliers of construction products and provides a complete and impartial design and supply service, with access to an unrivalled choice of roofing products. There would be few other teams able to take on such a project.

Whilst taking on the design liability for the roof, SIG Design and Technology would need to meet the original design intent of the architects and the planning consents. The new building would be a steel frame which would infill between all the existing buildings and incorporate significant movement in places of up to 20mm horizontally and vertically. Both of these requirements meant that the team would have to work collaboratively from the start.

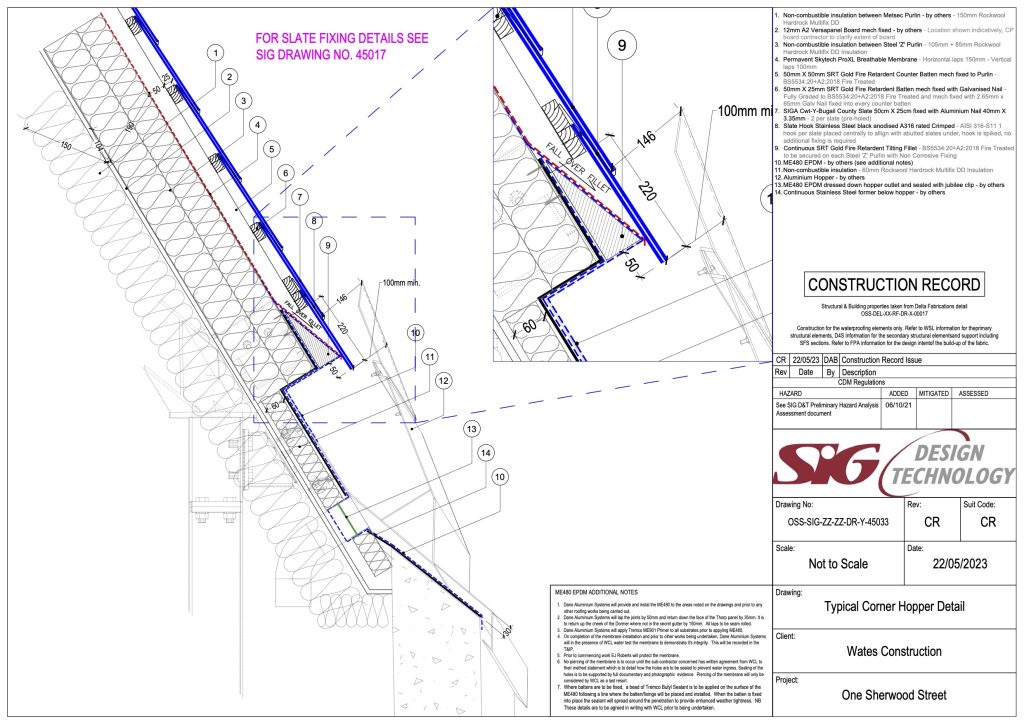

D&T’s technical team, supported by SIG Zinc and Copper and SIGA Slate and working collaboratively with E J Roberts roofing, developed over 300 details, working closely alongside Wates Group’s Project Manager, and the cladding and window manufacturers. With a variety of rebuilt historic facades involved, some of the detailing required on site resolution.

Just some of the huge crew of E J Roberts installers who worked on the project. The slate installers alone had over 100 years’ experience. Photo: E J Roberts Roofing

The materials

Slate

The slate used in Lucent W1 is a beautiful dark blue grey Welsh Slate from the historic Cwt-y-bugail quarry in Ffestiniog, covering a total of 1450m2 and designed to meet the requirements of BS 5534.

Main roof areas are covered in 500x250mm slates in the heavier 7mm County grade which has a riven leading edge, giving the geometric roofscape the familiar high-quality characteristics of historic buildings in the capital. All the slates are double nailed and hook fixed and incorporate bespoke snow guards to eliminate risk to pedestrians, and fire-retardant battens and counter battens were sourced from SRT Timber.

Some of the roof areas were to be of a very low pitch of 15 degrees, which is outside the British Standard. SIGA worked with specialist manufacturer Permavent to incorporate their Easy Slate system in these areas. The system includes a unique soaker between each slate which enables natural slates to be installed as low as 12 degrees.

Zinc

The flashing, gutters, balcony edges and other infills where slate cannot go are executed in zinc, alongside the cladding and some areas of roofing such as behind the historic facades. The Spanish zinc product elZinc Lava was chosen by the architect to be the best match to the Welsh Slates, enabling the roof planes to be read as an interconnected whole.

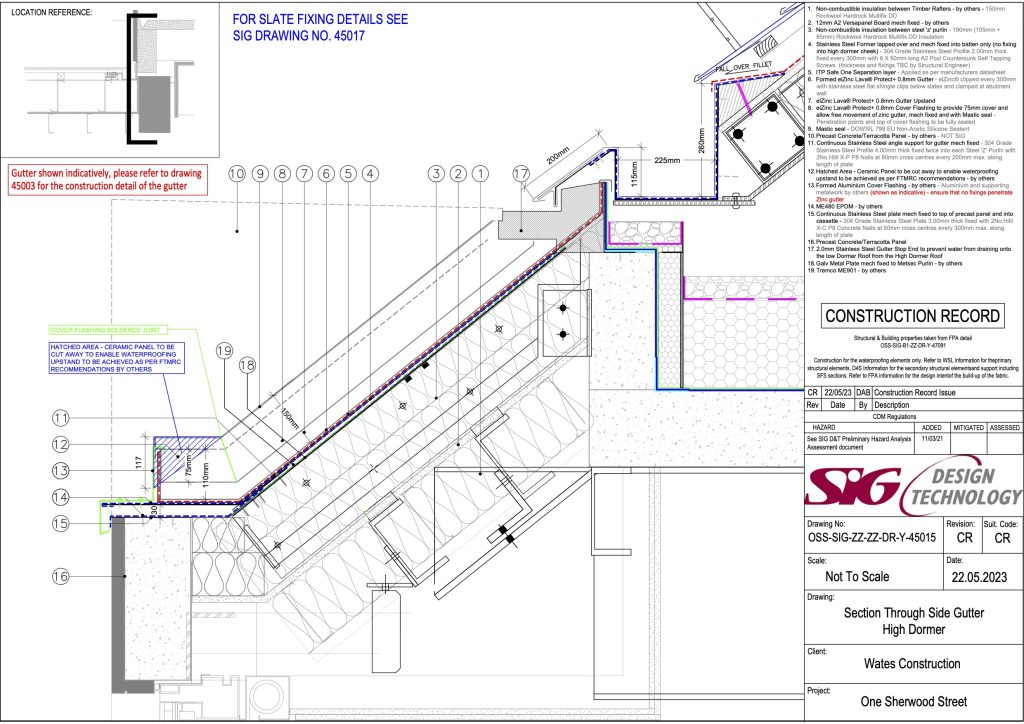

Unlike lead, zinc needs to be fully supported and incorporate a ventilation space. Indicative details prepared by the architect were all in lead, so the team developed hundreds of details in zinc for the myriad of different junctions and abutments, with inspiration and support from both FTMRC and the Lead Contractors Association. Along the perimeter of the zinc elements, thermal movement is allowed for by bespoke stainless steel support systems. Due to concern over hot works, the zinc was designed to be applied with minimal soldering.

Hot Melt

All 22 terraces and the flat roof at the top of the scheme, together with the waterproofing of the Building Maintenance Units behind the iconic Lights, are designed in IKO Permatec Hot Melt,

Hot Melt is a monolithic hot applied roofing membrane which is usually applied as part of an inverted roofing system, which was ideal for Lucent W1 where the waterproofing had to be concealed from view.

Hot melt produces a completely seamless waterproofing barrier without seams or lap joints and is formulated to last for the lifetime of a building. It also has the additional benefit of being able to be installed to zero falls, and in a complex project such as Lucent W1 also has the benefit of being simple to install without any complex detailing required.

The roofscape at Lucent W1 combines slate, zinc and hot melt in a unique way. Photo: E J Roberts Roofing

Rainwater

Shedding rainwater effectively is one of the major challenges with such a complex roof. SIG Design and Technology worked with a specialist drainage consultant to ensure that arrangements for rainwater would meet British standards. All the details were to some extent bespoke, and some required 3D design and manufacture of bespoke zinc hoppers to discharge rainwater either into concealed downpipes or onto the hot melt flat roofing areas. At all times the design team had to work to meet the design intent of the architect, the wish for waterproofing to be concealed, and the need for robustness in all details.

Here are just a few examples of the bespoke detailing used in Lucent W1:

Above the rooftop restaurant, rainwater from the restaurant roof and several other slate and zinc roof planes flows through a zinc gutter onto the hot melt flat roof at the end. This detail was particularly difficult due to the height restrictions and the wish not to impinge upon the restaurant interior:

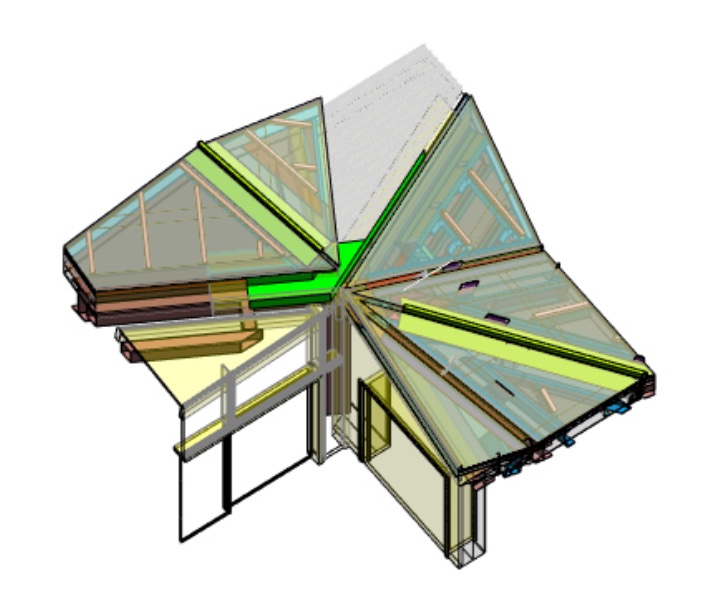

3D view of slate roof over restaurant (translucent grey) discharging into a gutter which discharges onto a hot melt roof behind (light grey) via a bespoke zinc hopper (green)

Behind the long Denman Street façade above a series of new dormers, a concealed gutter is penetrated by zinc chutes which allow much of the rainwater to terminate onto flat roofs, minimising the need to discharge rainwater between dormers:

Detail of secret box butter behind dormer (dotted line) showing how slate roof abuts the side of the dormer

At Rainbow Corner, on the corner of Shaftesbury Avenue and Denman Street, where the original intent was for a ceramic roof to step right down to ground level, the slate roof planes step down and convert seamlessly into articulated grey faience façade panels. Rainwater is collected in a gutter at the top of the dormer and additional gutters terminate into a bespoke 3D designed and fabricated zinc hopper which discharges through a concealed outlet.

The terraces, waterproofed in hot melt, were particularly challenging due to height restrictions. SIG Design and Technology developed a detail incorporating a drainage channel and specialist insulation which met the contractors requirements and the necessary U-Values.

Test Rig

The city centre location of Lucent W1 is subject to high wind speeds and therefore the roof design had to be designed to endure wind speeds of 100 miles an hour.

To ensure that the designs for the hot melt, slate and zinc roof elements would meet this requirement a test rig of a partial roof structure, based on the Shaftesbury Avenue elevation, was constructed at the Vinci Test Technology Centre in Leighton Buzzard and tested to European standards of weather-tightness. The test rig process went through several iterations and took nearly a year before the team were able to prove the robustness of the details.

The rig was pressure tested with simulated wind and driving rain, together with a vacuum system underneath that would identify any faults by drawing water through them.

Construction

Construction was to take place above and around three flagship retail units and behind the Piccadilly Lights, all of which would continue to operate, in one of the busiest parts of the city.

To meet the tight construction programme and a congested site, installation often had to be reprogrammed.

The nature of the project meant that details often had to be changed. On several occasions construction had deviated from the architectural and structural details modeled in BIM. Because much of the roof was bespoke and involved several existing or rebuilt historic facades, the design team had to measure up on site as they went along, sometimes developing new details to ensure they would meet the requirement of the as-built situation.

All materials were supplied through SIG’s extensive supply chain, largely via their outlet at Kentish Town. However the West End site location meant a separate holding area was designated for materials storage and roofing materials were delivered from there on an as-needed basis. All materials were craned onto the site, but the single crane was dismantled part way through the roofing works and so all 28,000 slates had to be stored on top of the building weeks in advance of their installation and worked around.

Completion

From an initial approach in 2019 through start on site in 2021, design and construction of the fabulous roof at Lucent W1 has taken over four years to complete. Construction alone required monthly and sometimes weekly visits, dozens of operatives, and hundreds of meetings online and in person.

Now that the project is completed, the huge collaborative team that made it happen can look back on an architectural masterpiece executed with unprecedented levels of commitment with pride at a job well done.

Project Participants

- Client: Landsec

- Architect: Fletcher Priest Architects

- Main Contractor: Wates Group

- Roof design and supply: SIG Design and Technology with SIGA Slate, SIG Zinc and Copper and SIG Roofing

- Specialist Roofing Contractor: E J Roberts Roofing Ltd

- Project Website: LucentW1

Recent Comments