Complete roofing and zinc solution from SIG D&T at Jersey Premier Inn

FDT Rhepanol PIB, Green Roofing, IKO Armourplan PVC, Zinc & Copper

Project: Premier Inn, Jersey

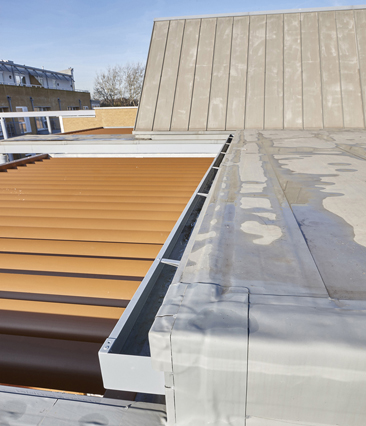

Roof membrane systems:

IKO Armourplan PSG PVC single ply 800m2

Hydrostop AH+ liquid waterproofing detailing

Sedum green roof

FDT Rhenofol CGv PVC single ply 80m2

Installer: KA BaileyZinc cladding:

elZinc Rainbow Brown 1600m2

Installer: Boss MetalsChartered building company: Camerons of Jersey

Travellers have another choice of modern, smart accommodation when they visit Jersey’s capital, with the opening of the island’s first Premier Inn in St Helier earlier this year. The four storey 91 room hotel, situated at the busy Charing Cross interchange near the town centre, features some distinctive external cladding in addition to a well-thought-out roof design.

SIG Design & Technology worked closely with Camerons, a 61-year-old Jersey-based chartered building company in the development of the new-build hotel’s roofing and cladding specification. SIG Design & Technology (SIG D&T) followed their eight-step design and build process, #perfectroof, from product selection and roof design expertise through to complete guarantees and planned maintenance.

Once the client brief was established, SIG D&T’s Specification Manager Christa Coe and Technical Support Manager Paul Jacobs worked together to develop the roofing specification.

Four roofing and cladding systems were selected. IKO’s Armourplan PSG system was chosen to waterproof 800 m2 of the main roof area. Armourplan PSG is a glass tissue reinforced polyester fleece backed PVC membrane suitable for use in a wide range of single ply roofing applications on both flat and sloping roofs. Armourplan PSG offers enhanced mechanical properties over standard PVC membranes and is completely UV stable […]

Conquering roofing complexity at Lymington Shores

FDT Rhepanol PIB

Project: Lymington Shores Housing Development

Developer: Redrow

Architect: APP

Roofing contractor: Flat Roofing Membranes Ltd

Waterproofing membrane: Rhepanol fk PIB single ply in RAL 7000Lymington Shores, located just off Hampshire’s Lymington Marina, is a high-end Redrow residential development which required a complex series of multiple single-ply roof specifications to its 12 villas and three apartment blocks of penthouses and duplexes.

Its prestigious location provides fine views of the River Lymington and beyond, and the housing complex is adjacent to the town’s railway station.

The architectural J42 specification included an intricate array of roof designs with 164 roof areas, high-impact aesthetics, sustainable membranes and high-quality workmanship.

With the large scale of the project spanning a total of 11,931m2, meeting programme schedules for the following trades was demanding. Flat Roofing Membranes worked closely with appointed architects, and SIG Design & Technology to develop the roof design, specification and all detailing.

Supplied by SIG Design & Technology, FDT’s Rhepanol fk membrane system was selected to meet Redrow’s requirements on sustainable choices of roofing materials. Rhepanol PIB is made from Polyisobutylene (PIB), a synthetic rubber, and is the only membrane currently available with a full Life Cycle Assessment that meets DIN EN ISO 14040-part ff, which demonstrates that it has no significant environmental impact at any time between its manufacture and eventual disposal.

In principle, Rhepanol fk is relatively easy to install, as it has a factory-manufactured, self-sealing edge, but the highest standards of workmanship were nonetheless required on this prestige housing development.

Four differing specifications over 12,000m2 of roof area

There were four different specifications of roof areas within the overall project. Flat roofed areas measuring 3,371m2 were waterproofed using FDT’s Rhepanol […]

Copper here in spirit at Guildford Crematorium

FDT Rhepanol PIB, Standing Seam

Project: Guildford Crematorium

Client: Guildford City Council

Roofing contractor: Breyer Group

Membrane: FDT’s Rhepanol fk finished with copper roof

Despite a 50% fall in incidents of copper theft – a result of Operation Tornado, which demands authentic photo ID from those selling to scrap metal dealers – the crime still costs the UK economy over £1bn a year. This was made painfully aware to Guildford City Council when its crematorium facility and Chapel of Remembrance on the outskirts of the town was targeted by thieves in 2011, and completely stripped of its long strip standing seam roof.

When it came to replacing the stolen copper, the council thought long and hard about its options for a facility that was never going to have a 24-hour security presence. Replacing the roof while respecting visitors’ sensitivities led Guildford council to look for a membrane equivalent.

The problem was strangely more complex than just changing the material for a cheaper one, such as zinc. ‘We were conscious of the fact that this was a place visited regularly by bereaved family and friends,’ recalls Guildford City Council project manager Tommy Parkes. ‘It was important to respect the fact that they might be sensitive to any radical changes. While it wasn’t part of the business case, we were keen to maintain the aesthetic, but had to minimise the chance of future theft.’

To meet both demands, the council opted for Rhepanol fk roofing membrane finished with its copper roof paint, which patinated in a matter of weeks to its characteristic green oxidised form. For the council it was a no-brainer. The £400,000 allocated to the works also involved […]

To meet both demands, the council opted for Rhepanol fk roofing membrane finished with its copper roof paint, which patinated in a matter of weeks to its characteristic green oxidised form. For the council it was a no-brainer. The £400,000 allocated to the works also involved […]

Garnet Chapel by Mario Botta – Protected by FDT Rhepanol

FDT Rhepanol PIB

Name of project: Garnet Chapel

Location: Penkenjoch, Austria

Membrane: Rhepanol fk

Architect: Mario Botta

Contractors: Robert Stadlmeyer GMBH & Co

Sculpture in an Alpine landscape

Above the Ziller Valley in the heart of the Austrian Tyrol, the Penkenjoch rises 2,095m above the Ziller Valley. In spite of the special logistic and climatic challenges this location provides, an architectural gem has been built in just three months: the Garnet Chapel designed by Mario Botta.

The idea for a small chapel on the sunny plateau of the Penkenjoch was born in 2011 when Josef Brindlinger and his daughter Christa asked the Swiss architect Mario Botta for a conceptual design, and construction works started in June 2013.

Situated on a rock spur, the chapel faces north towards the Ziller Valley below. The southern side points towards an artificial pond, which in winter is used as a water reservoir for producing artificial snow. Clad in a CorTen steel façade, the tiny chapel intentionally contrasts with its natural surroundings.

The crystal form of the chapel (a rhombic dodecahedron) is not a coincidence. In the mid 19th century Josef Brindlinger’s great-grandfather found several garnets of exceptional purity in this place. The form of a cut garnet, with twelve rhomboid surfaces, 14 corners and 24 edges, inspires Botta’s design for the chapel.

Striking façade

The chapel is built on a concrete base and consists of twelve rhombuses made of 120 mm thick plywood panels. On the outside, the façade is clad with 300 mm wide CorTen steel sheets at a10 mm spacing. The steel sheets rest on a total of 2,280 threaded rods anchored in the supporting structure. The façade alone weighs 17 tons; the supporting structure adds another 4 tons.

Reliable protection from the elements

To provide durable weather protection of […]

Skara Brae Project

FDT Rhepanol PIB, Green Roofing

Name of project: Skara Brae

Location: Orkney Isles

Client: Historic Scotland

Product: FDT Rhepanol hg green roof membrane

Size: 30 sq m

Architect: Historic Scotland

Installer: Greg Lister of GL Contracts Ltd

FDT harnessed the most modern roofing materials and advanced 21st century technological know-how to help preserve one of Europe’s most remarkable ancient monuments, 5,000-year-old Skara Brae.

The designated World Heritage Site, a fascinating commune of small interlinked stone dwellings, is one of the most-visited tourist attractions on the historic Orkney islands and offers up to 60,000 visitors a year an unparalleled taste of life in Neolithic Orkney.

With the site at the mercy of the fierce coastal elements, Historic Scotland, who care for the attraction, called on FDT to help overcome an unusual problem.

Neolithic carvings beneath the glass viewing roof of one of its famous domed homes were threatened by an unstable environment. Rhepanol hg was chosen to create a new watertight garden roof that blends in aesthetically and could be left undisturbed for up to 50 years.

Meydan Shopping Centre

FDT Rhepanol PIB, Green Roofing

Name of project: Meydan Shopping Centre

Location: Istanbul, Turkey

Client: Metro Group Asset Management

Product: FDT Rhepanol hg green roof membrane

Architect: Foreign Office Architects

Contractor: ICS Ic ve Dis Tic. Ltd. Sti Yukaridudullu-Umraniye/Istanbul

Size: 54,000 sq m

FDT played a key role in reshaping the urban landscape of Turkey’s most crowded city.

The vast 70,000sqm M1 Meydan Umraniye shopping and leisure complex, in Istanbul, is the country’s first shopping centre to feature a green roof – at 54,000sqm the largest of its kind.

Opened to the public in June 2007, the €34m Istanbul shopping centre has been hailed as one of the most exciting additions to Istanbul in modern times. The pioneering design won the process category of the 2008 European Business Awards for Environment for the geothermic technology used throughout the building.

FDT brought more than 30 years of technological expertise to the entire roofscape with its most advanced membrane, Rhepanol hg.

Rhepanol hg was specified because it provides a completely waterproof and root-resistant cover, allowing the roof to be planted up and thus offsetting some of the development’s carbon emissions.

Some 35,000sm of flat and sloping roofs were planted with vegetation, providing a much-needed rooftop green oasis for the city’s 14 million residents.

The remaining 20,000sqm is gravelled to provide a public square – complete with lush vegetation and a water feature which can be used as a skating rink in winter.

Installing the build up on 700 pitched areas – unusually high for green roofs – was a major success for FDT, who provided all the specification and technical support to the architect and owner

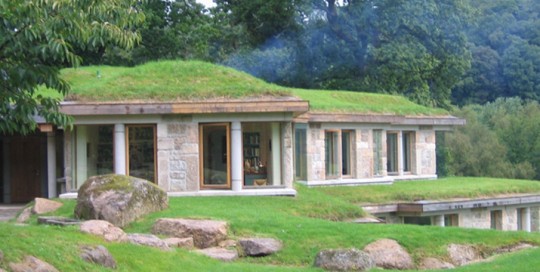

Manaton Project

FDT Rhepanol PIB, Green Roofing

Location: Manaton, Devon

Project: Award winning family home,

Client: Private individual

Architect: Peter Hall, Van der Steen Hall, Chagford

Main contractors: F I Joinery

Roofing Contractors: Western Counties

Roof Design & Supply: SIG Design & Technology

Type: Turf roof

Membrane: Rhepanol hg

Scope: 250 square metres over three roofs

Green innovation was at the forefront of designs for a stunning, award-winning family home created at Manaton, in the heart of secluded Dartmoor.

Rhepanol hg was selected for the three distinctive green roofs that help to shape the character of the large, four bedroom Devon property, which incorporates a raft of measures to minimise its environmental impact.

Architect Peter Hall of Van der Steen Hall in Chagford was asked to create the permanent house on the site of the owner’s well-used holiday bungalow. Materials from the bungalow were recycled and used in the new house.

He said: “We chose Rhepanol membrane and accessories for the complex and varied profiles of the roof planes – very different from the large, predominantly flat areas of typical grass-roofed office blocks – because of the help and advice we received from the accredited subcontractor and from the SIG Design & Technology representative.”

The roof, which covers a total of 250sq m, was key to creating a home in harmony with its rural setting. It complements the unique ground-hugging lines of the house and outbuildings, which are set down into the sloping wooded landscape.

The roof make-up comprised natural, local meadow grass and site-excavated topsoil on cuspated drainage layer/root barrier on Rhepanol hg with stainless steel gravel stop profile-adhered to membrane at perimeter and at intervals up steep slopes. The Rhepanol hg membrane was laid over softwood boarded roof, dressed into softwood eaves gutters and onto top of the fascia. (Rhepanol also forms fascia, cill and jambs of the window in the roof.)

Cedar Cottage

FDT Rhepanol PIB, Standing Seam

Project Name: Cedar Cottage

Location: La Rue de la Perruque, St Martin

Roofing Contractor: KA Bailey Roofing Contractors of Jersey

Product: FDT’s Rhepanol fk

Cedar Cottage is an extensive new-build private house in a rural area overlooking the sea in St Martin, Jersey. The finished roofing is over-looked by other properties so the roofing membrane had to be aesthetically pleasing and in keeping with the location.

The architect, Design Plus, specified a standing seam finish in Rhepanol fk for its aesthetic appearance. FDT’s Rhepanol fk single ply roofing membrane is exclusive to SIG Design & Technology. Thermataper TT47 tapered insulation from Kingspan and Felt VCL from Polyglass were also supplied by SIG Design & Technology.

K A Bailey Roofing Contractors of Jersey selected Rhepanol in PIB for its environmental credentials; it is the only membrane to offer the full Life Cycle Assessment and is fully recyclable at the end of its life.

The installation demanded high levels of operative skill. The Cut to Falls insulation was bonded to the VCL in separate layers. Due to its thickness, the product needed to achieve U Values of 0.14.

Rhepanol was then cut to size to match up with the gutters and laps. To create an attractive finish to the roof, the standing-seam extruded profiles were positioned in straight lines to emulate a lead standing-seam roof build up.

Rhepanol is attached to the next sheet of membrane by a unique self-sealing edge. The seam chemical welds to display immense textile strength.

Worcester Park

FDT Rhepanol PIB, Standing Seam

Project Name: Worcester Park, Salisbury Road, Surrey

Roofing Contractor: Flat Roofing Membranes of East Sussex

Rhepanol fk from SIG Design & Technology was chosen to waterproof five areas of roofing with a total area of 949 m2 on a residential scheme at Worcester Park, Surrey.

Built by a national house-builder, the residential complex at 68-72 Salisbury Road comprises three new-build blocks of terraced-style homes. Two identical blocks comprise six units, each with a rear and front balcony (these blocks are designed with shallower barrel roof than shown in the image) and one block of five units, each with a rear balcony (as shown).

This series of five types of roof areas demanded a wide range of knowledge and skills from the installers, Flat Roofing Membranes of East Sussex. The roof design comprises flat roofed areas, curved and barrel-vaulted sections, dormers, timber decking to balconies, many areas of intricate detailing and pitches up over 45°. Speed of installation was critical despite adverse weather conditions.

The roof build-up is waterproofed by Rhepanol fk in light grey, a unique single ply membrane system that can emulate a metal roofing effect. In this application, Rhepanol fk mimics a lead standing seam roofing system.

There are five areas of roofing with a total area of 949 m2. They comprise:

- 245m2 barrel type roofing; 100mm thermal insulation, FDT vapour barrier fk and waterproofed by 2.5mm Rhepanol fk in light grey

- The 430m2 main roof build-up comprises polythene VCL, 120mm insulation which is mechanically fixed; and Rhepanol fk waterproofing

- Dormers and cheeks are an equal build-up; but without VCL or insulation

- There are 16 terraces measuring 160 m2 with plywood substrate and 100mm thermal tissue-faced PIR insulation

- 102m2 of balconies – all 17 measuring 6m2 each with timber decking over polythene […]

Lakeside Manor Care Home

FDT Rhepanol PIB, Standing Seam

Name of project: Juniper Court Extra Care Centre

Location: Jersey

Architect: Robert Adams Architects

Main contractor: AC Mauger

Roofing contactor: KA Bailey Roofing Contractors of Jersey

Product: FDT’s Rhepanol fk in light grey

Lakeside Manor Care Home & Independent Living Apartments at St Peter on the Channel Island of Jersey is a luxury new build project by AC Mauger, one of the largest main contractors on the islands.

Robert Adams Architects from the UK selected Rhepanol fk single ply from SIG Design Technology for its aesthetic quality plus speed and ease of installation for multi-use roof applications. Jersey based Ken Bailey was appointed as roofing contractor.

At Lakeside Manor Care Home there are two main roof areas to the project each measuring some 200 m2 . Rhepanol fk in light grey was bonded to the timber deck and fitted to the gutters on either side; a lead capping encloses the total area which is waterproofed Rhepanol fk.

Rhepanol fk is the only PIB single ply roofing membrane to have a full Life Cycle Assessment in accordance with ISO 14040 part ff proving its environmental credentials as the world’s most sustainable single ply. Several balconies measuring approximately 400 m2 in total also received Rhepanol fk waterproofing.

All of the gutters on the balconies were also waterproofed in Rhepanol fk and these were then coated with Rhepanol Copper Paint to prevent the build-up of algae and moss that can accumulate when falls in the gutter are limited.

Ken Bailey said: ‘Rhepanol is a universal membrane that is well suited to the task. Our main practical challenge was to synchronise our work with following trades, carpenters and lead