Garnet Chapel by Mario Botta – Protected by FDT Rhepanol

Name of project: Garnet Chapel

Location: Penkenjoch, Austria

Membrane: Rhepanol fk

Architect: Mario Botta

Contractors: Robert Stadlmeyer GMBH & Co

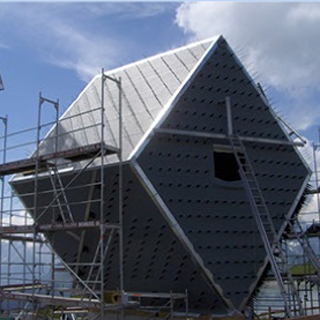

Sculpture in an Alpine landscape

Above the Ziller Valley in the heart of the Austrian Tyrol, the Penkenjoch rises 2,095m above the Ziller Valley. In spite of the special logistic and climatic challenges this location provides, an architectural gem has been built in just three months: the Garnet Chapel designed by Mario Botta.

The idea for a small chapel on the sunny plateau of the Penkenjoch was born in 2011 when Josef Brindlinger and his daughter Christa asked the Swiss architect Mario Botta for a conceptual design, and construction works started in June 2013.

Situated on a rock spur, the chapel faces north towards the Ziller Valley below. The southern side points towards an artificial pond, which in winter is used as a water reservoir for producing artificial snow. Clad in a CorTen steel façade, the tiny chapel intentionally contrasts with its natural surroundings.

The crystal form of the chapel (a rhombic dodecahedron) is not a coincidence. In the mid 19th century Josef Brindlinger’s great-grandfather found several garnets of exceptional purity in this place. The form of a cut garnet, with twelve rhomboid surfaces, 14 corners and 24 edges, inspires Botta’s design for the chapel.

Striking façade

The chapel is built on a concrete base and consists of twelve rhombuses made of 120 mm thick plywood panels. On the outside, the façade is clad with 300 mm wide CorTen steel sheets at a10 mm spacing. The steel sheets rest on a total of 2,280 threaded rods anchored in the supporting structure. The façade alone weighs 17 tons; the supporting structure adds another 4 tons.

Reliable protection from the elements

To provide durable weather protection of the chapel, a high-quality polyisobutylene based (PIB) synthetic roof waterproofing was installed behind the CorTen steel sheets.

Local Specialist Roofing Contractors Robert Stadlmeyer GMBH. & Co. carried out the waterproofing works. They installed the tested and proven premium roofing membrane Rhepanol® fk made by German manufacturers FDT. The membrane is equipped with an integrated synthetic fleece and a prefabricated self-sealing edge. Flexibility at temperatures as low as minus 60 °C significantly facilitate material handling of the membrane, and even in extraordinary weather the membrane features outstanding stability and durability highly favourable for such a location.

Rhepanol fk also has environmental benefits and an extremely long lifespan in use. The environmental profile indicates that Rhepanol fk is a permanently UV and ageing resistant synthetic roofing membrane and does also not contain any plasticizers or halogen fire proofing agents. An independent life cycle assessment according to ISO EN 14040-49 showed that neither the raw materials, nor the production process or the processing and long-term use of Rhepanol® fk cause any significant environmental impact. Even after its useful life, the membrane can be fully recycled.

Small area – big challenge

Although only 412 square metres of roof and façade needed waterproofing, this task turned out quite a challenge for the roofers. Aside from the demanding site-specific logistics, extraordinary weather conditions like snow in the middle of August had to be considered.

Waterproofing the rhombic plywood panels lying on the ground with Rhepanol® membranes proved to be relatively easy. To prevent wind uplift, the membranes were bonded in strips to the supporting timber structure with the permanently elastic synthetic rubber based FDT roofing membrane adhesive.

Some of the waterproofing works had to be carried out under adverse weather conditions and full adhesion of the roofing membrane adhesive would often take one or two days. The roofers therefore used the product’s Gripfix system to provide additional mechanical fastening, enabling the cross laminated timber panels to be waterproofed on time and ensure the elements were immediately ready for installation as required.

Once the initial waterproofing was carried out, the threaded rods to support the CorTen Steel cladding were anchored in half of the elements still lying on the ground. In order to achieve quick, accurate and permanently waterproof flashing against the rods, the roofers employed a preformed detail perfectly adapted to the roofing membrane: the FDT lightning conductor sleeve with Rhepanol collar.

While one half the structural panels had their threaded rods fitted on the ground, the remainder where attached and waterproofed when the panels were in place using a scaffold.

Upon complete installation of the elements, the corners were additionally secured with special nail boards. Then the roofers sealed the 14 corners and 24 edges with Rhepanol cover tape and Rhepanol sealing tape. At this point chapel was then completely weatherproof, ready for the installation of the steel supports and the corten steel sheets.

The magic of light and geometry

The interior of the consecrated chapel is approached through the basement entrance. A small staircase leads the way up to the prayer room. In an instant, the plain and precise geometry of the interior reveals itself to the visitor. Through a central opening light from above floods into the room, washing the larch-clad walls with warm colour. The movement of light throughout the day lends the perfectly proportioned room an air of magic.

For Mario Botta architecture is something that replaces nature and, as such, is always in struggle with nature. To him, making architecture blend in with nature, making it quasi indiscernible, would be wrong. The Garnet Chapel, a sculpture in an Alpine landscape, is the first building he has realised in Austria, and an impressive example of this approach.