“In this issue, can I introduce to you Andrew Bright our National Business Development Manager for Liquid Waterproofing Systems.

“In this issue, can I introduce to you Andrew Bright our National Business Development Manager for Liquid Waterproofing Systems.

With decades of specialised roofing experience, Andy was appointed to his new role back in 2017. He leads a strong team of area field technicians namely Jamie Dunsmore, Jordon Hughes, Billy Lavender, Billy McNiven and Danny Meadows. Liquid products are also supported by our seven area specification managers, Sara Jelly on training and our technical team (including our newest recruit, Emma McLaughlin) which is led by Daniel Bosworth.

Read on about our wide range of liquid waterproofing systems, together with their features and benefits. Our technical director, Steve Cleminson offers guidance on how important planning, preparation, and priming are in making sure that you do a top-notch job. There’s a handy table which reminds you of the correct Installation temperatures for specific products and their drying times. And a ready reference chart showing how to achieve correct coverage rates.”

Mike Crook Trading Director

![]()

RW6liquidchoices

SIG Design & Technology has a comprehensive range of liquid waterproofing systems to choose from, that we’re quietly confident that we’ve got at least one system to suit the job you’re working on.

SIG Design & Technology has a comprehensive range of liquid waterproofing systems to choose from, that we’re quietly confident that we’ve got at least one system to suit the job you’re working on.

The SIGnature PU Liquid Waterproofing System is a revolutionary, fast curing, pure elastomeric, hydrophobic, polyurethane flat roofing system is available in two product formats.

The SIGnature PU Liquid Waterproofing System is a revolutionary, fast curing, pure elastomeric, hydrophobic, polyurethane flat roofing system is available in two product formats.

SIGnature PU-20 Liquid Coating Kit comprises two components which when mixed together create a single coat application, rapid curing liquid roofing membrane which can offer a 20-year guarantee. NB: the accelerator must be used and thoroughly mixed into the liquid membrane immediately before application. The SIGnature PU-10 Liquid Coating is a single component liquid membrane, single coat application with a 10-year guarantee.

Both SIGnature PU Liquid Coatings can be applied as a single coat (PU-20 Kit with accelerator component added) with only localised reinforcing as required, creating a bubble-free and durable liquid applied roofing system.

SIGnature liquids can be applied all year round above 5°C and are cold applied – no heat or flame required. They offer excellent elasticity and tensile strength and guarantees up to 20 years (product specific) when installed by a DATAC Contractor.

Hydrostop AH+ is a one component liquid waterproofing system which offers significant advantages over conventional PU and PMMA systems and a warranty up to 25 years. Very low odour and fast-curing, it is fully reinforced with a polyester fabric. It can be applied under practically any conditions, even on cold days and on most surfaces. There are no COSHH or disposal issues.

Hydrostop AH+ is ideal for small scale or large commercial projects, whether they are new or refurbishment.

The Vulkem® Quick System is a crack-bridging, UV and wear-resistant waterproofing system with aesthetic appeal.

The Vulkem® Quick System is a crack-bridging, UV and wear-resistant waterproofing system with aesthetic appeal.

The different components that make up the Vulkem® Quick System cure to form a highly-elastic, foot trafficable waterproofing system which is suitable for installation on old or new concrete, tiles, metal, wood, epoxy and other types of existing deck coatings.

Typical applications include use on areas where there will be frequent pedestrian traffic including balconies, terraces, pedestrian bridges, stadium decks, entrances and exits, staircases etc.

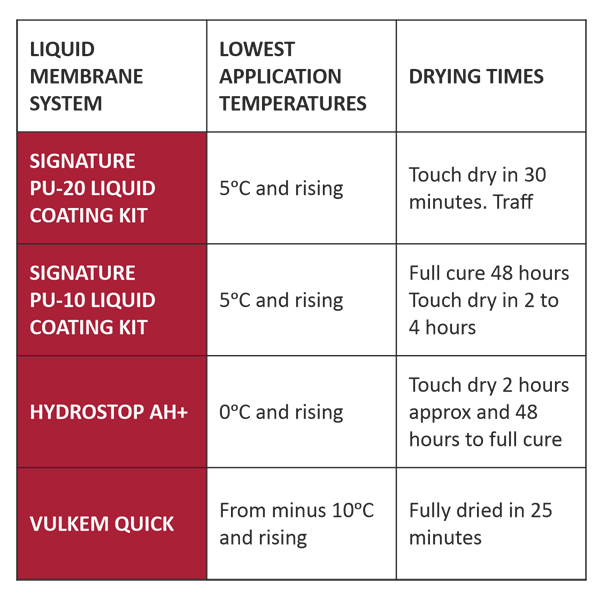

Installation temperatures and drying times for liquids

Below is a rough guide to lowest temperature applications and drying times. For optimum product performance, you must refer to the manufacturer’s data sheet which is available here

RW6threepsleadtooptimumperformance

By Steve Cleminson, SIG Design and Technology’s Technical Director

By Steve Cleminson, SIG Design and Technology’s Technical Director

There are three essential steps which need to be addressed before you start applying the liquid. They are the three Ps i.e. planning, preparing the surface to receive the liquid and priming areas as necessary.

Planning

Firstly, planning. Where do I start? Look at the roof and work out where are your access and egress points going to be. You don’t want to walk on newly-laid product or store lots of materials on the pristine new roof surface.

Preparation

When preparing, you should prep in the morning (especially if the temperature is below that recommended for application) and wait for drier or warmer weather if its forecast later in the day etc. before applying product. See chart on minimum temperatures and curing times. Ask yourself, do I have the necessary gear to prepare and

clean the existing surface (if it’s a refurbishment project). Is there any patching to do etc?

Priming

The correct primer needs to be selected for the liquid waterproofing chosen. For example, the SIGnature range has two options of general surface primer – same day or next day. Please refer to the relevant data sheet here

RW6casestudyah25waterproofsbalconies

Hydrostop AH+ cold applied liquid waterproofing was chosen by Knight Asphalte to waterproof 170 crescent shaped balconies to River Walk, an elegant new development of 116 high specification apartments on the Thames at Pimlico.

The balconies provided a unique challenge to the contractors. Each one is a different crescent shape, but all have tight tapers at the edges to ensure the continuity of flow of the sinuous limestone cladding externally.

Hydrostop AH+ was the ideal choice. Firstly, with many cleats and bolts to each balcony, a sheet membrane solution would have been excessively complicated; a liquid becomes homogenous. The contractors would not be able to revisit after installation as it would be hidden behind the cladding and fixing process, so product performance confidence was critical. Using a liquid, the prefabricated steel ends could be waterproofed prior to installation followed by waterproofing the remaining areas. A cold applied liquid would avoid issues with fire risk and spillage associated with hot systems, particularly in such confined spaces.

RW6newliquidstrainingfacility

RW6contacts

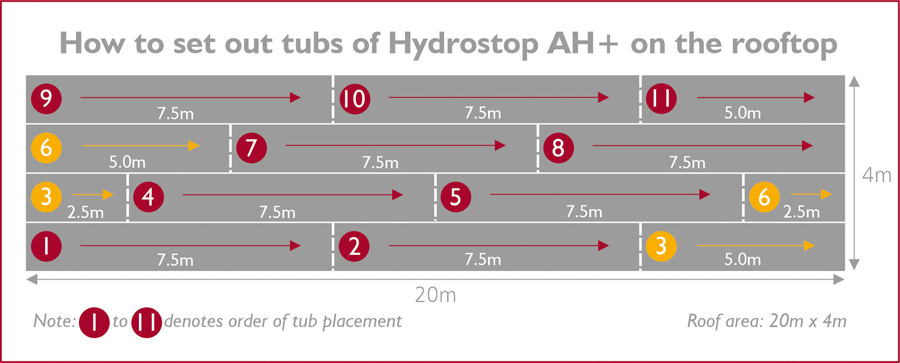

SIG Design & Technology is setting up a dedicated liquids training facility at Capital Roofing in Greenwich London. Due to open this month, the new facility will offer installers training in our full range of products; i.e. both SIGnature liquid waterproofing systems, Hydrostop AH+ and Vulkem Quick. Hydrostop AH+ training will also still be available at the Shepshed training academy.

SIG Design & Technology is setting up a dedicated liquids training facility at Capital Roofing in Greenwich London. Due to open this month, the new facility will offer installers training in our full range of products; i.e. both SIGnature liquid waterproofing systems, Hydrostop AH+ and Vulkem Quick. Hydrostop AH+ training will also still be available at the Shepshed training academy.

Demonstration by Danny Meadows, Area Field Technician

Daniel Bosworth, Design Manager

Emma McLaughlin, Technical Support Advisor

Sara Jelly, Roofing Academy Manager 01509 501 738

General enquiries: 01509 505 714

Technical help: 01509 501731

Email: [email protected] or [email protected]

Recent Comments