Liquid Flat Roof Systems – Get the Insulation Right

Liquid flat roof systems are increasing in popularity, but they can still present a challenge to the specifier to get them properly installed. Here we look at that challenge and suggest one way to meet it – by specifying the correct insulation board.

The Benefits of Liquid Flat Roof Systems

There are many benefits to liquid waterproofing. On more complex roofs, such as those with many penetrations, liquids can overcome many of the issues related to fitting membranes to complex junctions. Most liquids can be applied cold, avoiding the need for hot works, and some are odour free. Correctly installed and maintained, they can provide a long-term life often in excess of 25 years, and in refurbishment situations liquid systems can provide considerable savings on roof replacement costs.

Liquid roofing products are backed up by years of R&D and the support of organisations such as the LRWA (Liquid Roofing and Waterproofing Association) that promotes the benefits of liquid waterproofing and provides guidance on best practice.

Liquid roofing products are backed up by years of R&D and the support of organisations such as the LRWA (Liquid Roofing and Waterproofing Association) that promotes the benefits of liquid waterproofing and provides guidance on best practice.

As a result of these benefits, liquid applied roofing membranes are increasingly popular; the estimated value of liquid waterproofing installed in the UK has increased 97% in the last six years (Source: AMA Research).

“The estimated value of liquid waterproofing installed in the UK has increased 97% in the last six years”

What could go Wrong?

Some specifiers have had bad experiences with liquid flat roofing systems, even with such a high-quality product. Correct installation is crucial, but not a problem if you specify the use of an accredited contractor scheme such as our own DATAC scheme. DATAC accredited installers will be well trained in best practice for liquid and membrane installation.

The question is, why do liquid flat roof systems sometimes fail? When things do go wrong with a liquid roof, it is often a problem with the substrate and its installation, not with the liquid itself.

More often than not, problems with the substrate are caused by one or more of the following:

- a failure of the bond between the boards of a substrate;

- crushing to the surface of the insulation boards;

- misaligned edges of insulation boards.

Liquid applied coatings are typically less than 2mm thick and are therefore vulnerable to such imperfections in the substrate.

The joins in the substrate are particularly vulnerable for a number of reasons:

- Any imperfections in the surface are likely to occur at board edges, either by poor fixing or poor alignment of the boards whilst installing;

- Insulation board edges are the most liable to crushing and damage;

- If not accurately installed, two abutted edges of insulation can leave an air gap where any water vapour trapped during installation can rise up to the board edge and create a vapour pocket that can’t escape. This may be seen as a visible bulge under the membrane.

When things do go wrong with a liquid roof, it is often a problem with the substrate and its installation, not with the liquid itself.

How to ensure Liquid Flat Roofing Systems are correctly Installed

How can you ensure your specification of a liquid flat roofing system, whether for new build or a refurbishment project, won’t be affected by poor substrate? We recommend that specifiers:

How can you ensure your specification of a liquid flat roofing system, whether for new build or a refurbishment project, won’t be affected by poor substrate? We recommend that specifiers:

- Specify an insulation product which combines insulation and panel surface in one, avoiding crushing issues, and

- Specify a product that is easy to install accurately on site, where a turn of a screw won’t cause misalignment of boards.

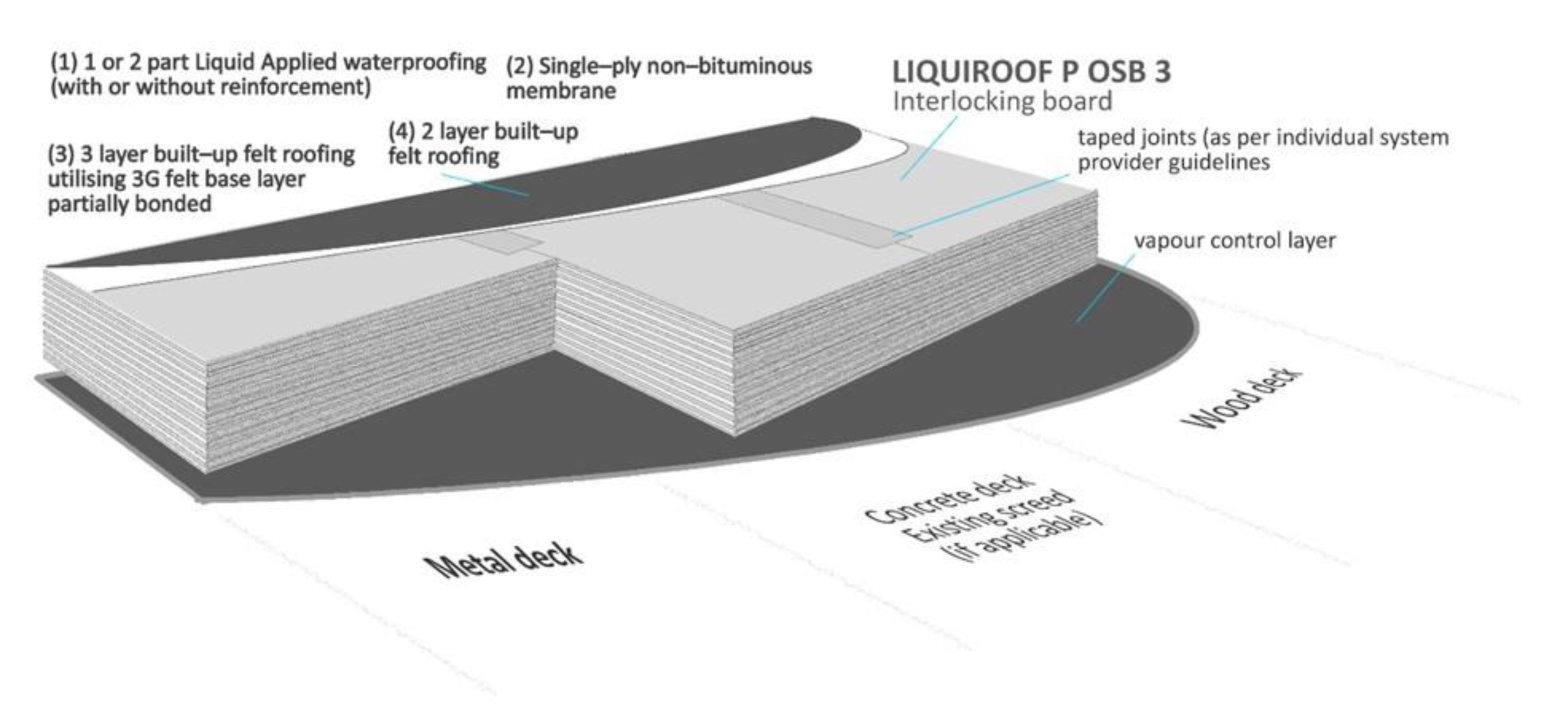

This is why we’re so pleased to be able to exclusively offer the innovative LIQUIROOF P OSB 3 – a unique PIR insulation board whose clever design resolves any issues with deflection, delamination and misalignment. This product is ideally suited to liquid roofing.

What is LIQUIROOF P OSB 3?

LIQUIROOF P OSB 3 is a fully supported interlocking combined PIR and OSB3 board which interlocks on all four sizes, delivering a super-flat ‘tabletop’ surface for the direct application of liquid and other roofing systems, with no carrier layer required.

The boards are quick to install as the combined T&G board joints and finger joints in the insulation allow them to automatically align correctly, no longer relying on the correct turn of a screw.

Once installed, the boards slot together and act as a single large board, providing strength and product integrity. This means there is

- No stress at the joints

- No surface crushing – during installation, maintenance or additional works

- No delamination, and

- No vapour drive to the edges.

Specifying LIQUIROOF P OSB 3 insulation boards on your flat roof will increase the speed of installation, increase the accuracy of the installation, and reduce the risk of failure on liquid flat roof refurbishments.

What is more, specifying LIQUIROOF P OSB 3 will give you peace of mind and allow your clients to access all the benefits of the latest liquid waterproofing systems with confidence.

Find Out More

LIQUIROOF P OSB 3 Is available in various thicknesses from 38mm (30mm PIR, 8mm OSB) up to 188mm (180mm PIR, 8mm OSB), giving U-Values between 0.12-0.46 W/m2K. The boards can also be laid over other PIR boards if required.

Tapered insulation options are available, and the boards can be cut to size. Board sizes are typically 1200x2400mm and 1200x1200mm but other sizes are available.

- Find out more about LIQUIROOF P OSB 3 and download product information on our dedicated LIQUIROOF pages.

- Visit our Liquid Waterproofing Pages to find out about the waterproofing products we recommend.

It’s easy to see why liquid flat roofing is becoming so popular, especially with the lifespan. As with any roofing job however, it’s best to call in the professionals if you don’t want problems cropping up down the line from installation mistakes.