Leaking Roof? Check it isn’t Interstitial Condensation

We’ve been talking to Ian Dryden, Business Development Manager at SIG Roofing, about an increasing concern he has for flat roofs built in the 1980s and early 1990s, and incorrectly refurbished roofs which appear to be leaking, but they aren’t. Ian has been coming across a number of these roofs requiring refurbishment. They are suffering from a condition which has been misdiagnosed for years.

Here’s an example of a leaking roof from a Glasgow School.

Saturated Insulation

This 3000m2 flat roof to the 1980s built school was constructed with a composite panel used as a deck together with a pre-laminated underlay. The school has been leaking for well over 16 years but the leak could not be found. Several overlays of new membrane have been applied over the years, each without success.

Ian inspected the roof by taking a number of core samples and discovered that there was no VCL (vapour control layer) in the construction. He then inspected a lap between the composite panels and discovered there was no butyl mastic seal to the laps either. When the roof was designed the designers may have argued that there was no need for a VCL as the panel is factory bonded, but every lap and penetration through the deck should have been fully sealed with butyl mastic. If there is no control to water vapour travelling through the roof, then it is at risk of interstitial condensation.

What is Interstitial Condensation?

Condensation is when water vapour condenses into liquid. This is seen, for example, when a cold glass of water meets warm, moist air. Droplets of water collect on the surface where the lower temperature produces an energy transfer from the water vapour to the colder surface, and the vapour condenses into a liquid at that surface.

“Interstitial” means occupying “interstices” – small gaps or cracks. So Interstitial condensation occurs within the fabric of a building, at the point (known as the dew point), where the atmospheric temperature of a given concentration of water vapour drops to a point when water droplets begin to condense and dew can form.

Interstitial condensation is different from surface condensation such as that caused by cold bridging, and its occurrence within the roof or wall structure of a building is difficult to detect without investigation.

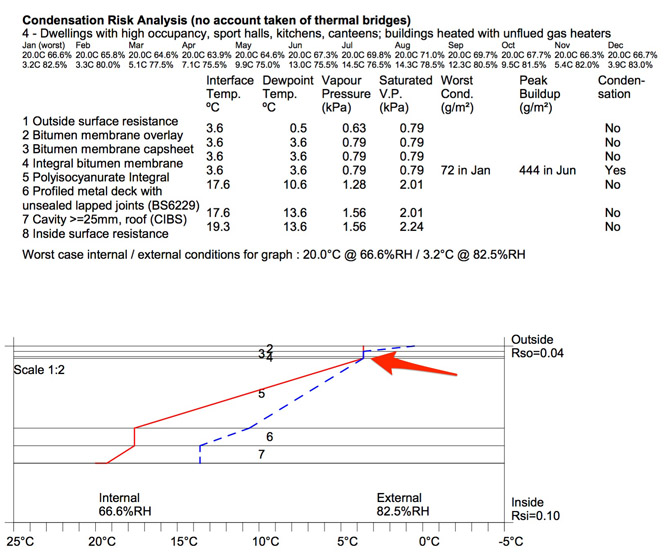

Condensation Risk Analysis for the Glasgow school with the dew point indicated under the membrane. Calculations supplied by CTF Insulation

What Interstitial Condensation can do

After inspecting the whole roof of the Glasgow school, Ian had to conclude that there was no way for the water to get into the roof other than condensing out of the water vapour travelling up through it. The remaining roof structure was correctly detailed, there were no weep holes for water to get in, and the waterproofing was in excellent condition. Wherever you cut a hole in the roof, it is saturated with water inside.

Condensation between membrane layers causes delamination

Failed timber deck caused by interstitial condensation

The costs of misdiagnosis are high. Every so often 30-40m2 of ceiling tiles have to be replaced as they become ruined by the leaks. The water follows the troughs in the metal deck, tracks along the laps and leaks under the gutters which is the lowest point. As a result, a leaking gutter has been suspected, and long lengths of gutter have been re-felted to no effect – the water keeps coming. Indeed, a complete overlay of the roof with an additional membrane increased the vapour resistivity of the surface and compounded the condensation problem.

With 2000 children breathing in the school for sixteen years, the considerable additional weight of all that water can also put significant load on the roof. The calculations show this amounts to an annual moisture accumulation of 0.44kg/m2, or nearly half a litre a year in every square metre of roof.

This is just one of Ian’s projects. In another school with a cold roof (pictured), a 250mm unventilated ceiling void has caused the timber deck to rot from the inside. For 5 or 6 years the 1600m2 deck has gradually rotted and now 90% of the timber deck has completely failed. If the problem had been identified earlier the deck would have been saved, but now the entire roof including the deck will have to be replaced.

How to find out if you have Interstitial Condensation

What to do if you come across a leaking roof from the 1980s/90s or a roof from that period that has been overlaid? Here is Ian’s advice.

1. Have a proper investigation

Don’t assume that the leak is coming from a failed membrane, or a leaky gutter – you may be mistaken. Make sure an experienced specialist is involved in investigating the leak. They will cut a core sample – a hole in the roof which will enable them to identify the buildup and check the condition of the layers of roof.

2. Look for a VCL

The core sample will enable your specialist to check for a VCL. If there is no Vapour Control Layer, there is a very good chance that interstitial condensation may be the cause.

3. Look for Seals on a Metal Deck

If the roof is constructed of composite sheets on a metal deck, check whether they are fully sealed. They may not be the case, especially if the roof was constructed in the 1980s and early 1990s. If the seals are not there, warm air may be travelling up inside the construction and condensing where it hits the dew point.

4. Cold Roof? Check the Ceiling Void is Ventilated

If there is a ceiling void, especially with a cold roof, is it ventilated? Many were not in this period, and without ventilation warm moist air will condense onto a timber deck and rot the roof from the inside.

5. Get an Interstitial Condensation Risk Analysis

Get an Interstitial Condensation Risk Analysis carried out. This is something we do for all our new roofs as well, as part of our design service. The analysis will determine the dew point and you can check where the condensation is happening in the report. If the dew point is within the buildup, you have a problem.

6. Determine if you’ve got a leak or condensation

If all your investigations come back fine, then a leak is most likely the cause. “Even when I find an obvious leak, I always check the dew points,” says Ian. “Some of the VCLs were made to BS7471f and 1b which are little more than a vapour check.” The lack of a proper metal lined VCL can lead to a swimming pool on your roof.

7. Don’t forget to check with Roof Refurbishment Overlays

When you’ve determined the cause of water arriving inside the building, you’re in a position to make appropriate repairs. But when Refurbishing a Roof, make sure you carry out an interstitial condensation risk analysis on the new buildup to make sure that it will not result in condensation within the structure.

“I think people have forgotten what an important issue interstitial condensation is.” Ian told us, “you must make sure you take the dew point right to the top of the buildup”. Make sure you ask for the report, and check it carefully. “Architects often ask me why I’m putting 100mm insulation in a refurbishment rather than 50mm” says Ian. “You may not know about the condensation for 10 or 15 years, until the roof caves in.”

More Information

- If you’ve got an unexplained leaky school, office or commercial roof, why not get the specialists in? Contact us to arrange an inspection.

- Read about how to avoid genuine leaks in your flat roofs in a great post by Steve Cleminson.

- Interstitial Condensation is one of the many checks we carry out as part of our design service. Find out how to get design expertise and meet the regulations as part of our 8 Steps to a Perfect Roof.

Interstital condensation is definitely more common than some people realise. To reduce condensation, a breathable membrane is a good idea. A breathable membrane installed on the cold side of the insulation does much the same job as conventional sarking such as keeping rain, snow and dust from getting into the roof and wall cavities, but also lets the vapour escape, allowing the building to breathe.

Hi Nice Day for you, I just checking the article to find an inspiration or an exciting post. Remarkable post, express gratitude for sharing.

Condensation is a really big problem, causes expensive damage to roofs! As a roofer I see this damage a lot, some very good tips in this article.

Thanks for the comments Steve.

You might be interested in our more recent post about a build up issue that caused interstitial condensation: https://www.singleply.co.uk/failed-flat-roof-problems-split-build-up/

I’ll take a look thanks mate

Nice article/tips. We see the adverse effects of interstitial condensation quite often.

Thanks Joshua – have you come across this issue? https://www.singleply.co.uk/failed-flat-roof-problems-split-build-up/

Hi. Can Interstital condensation exhibit as actual dripping liquid that pours from a point, running down a wall, continuing as a stream along the floor.

Hi Dean, yes it most certainly can. The amount of moisture that condenses can be quite considerable. If this is your roof you’d be best to get a professional survey to identify whether it’s a leak or interstitial condensation that is causing the problem.

[…] roof is not leaking, it’s got interstitial condensation. Follow this link to find out […]